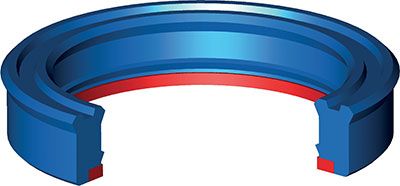

SDA

This seal is mainly used with high pressure and the backup ring o sets large gaps without extrusion.

Wear and dry run are largely prevented by additional lubricant retained within the gap created by the secondary lip. In some cases this second sealing lip may even act as a substitute for a costly tandem sealing system when complete sealing under certain working conditions can only be achieved by two seals placed one behind the other in separate housing.

It’s designed to be less sensitive to pressure fluctuations than typical “U” seals.

The material used to produce this seal is a polyurethane compound that ensures excellent properties on wear-resistance, extended service life and resistance against extrusion.

- Very high resistance against extrusion(backup ring)

- Good sealing performance as well as at low pressure

- Extended service life

- Good temperature resistance

- Insensitive to structural deflections

- Easy installation without expensive auxiliaries

SDA Seal Model

SDA 25 33 5.8 SDA 36 46 7 SDA 40 48 8 SDA 40 50 10 SDA 40 52 10 SDA 40 55 10 SDA 45 53 9.5 SDA 45 55 10 SDA 45 60 10 SDA 50 60 10 SDA 50 65 10 SDA 55 65 10 SDA 55 70 9.5 SDA 56 71 11.5 SDA 60 70 12.5 SDA 60 75 12 SDA 60 80 12 SDA 63 75 12 SDA 63 78 11.5 SDA 63 83 12 SDA 65 75 12 SDA 65 80 11.5 SDA 70 80 7 SDA 70 85 12 SDA 70 90 13.5 SDA 75 85 12 SDA 75 90 12 SDA 75 95 13.5 SDA 80 88 9 SDA 80 95 11 SDA 80 96 9.5 SDA 80 100 11.5 SDA 80 100 13.5 SDA 90 105 8.5 SDA 90 105 12 SDA 90 110 12 SDA 95 115 13.5 SDA 100 108 8 SDA 100 110 12.5 SDA 100 113 12.5 SDA 100 115 11.5 SDA 100 120 13.5 SDA 110 120 13.5 SDA 110 125 12 SDA 110 130 11.5 SDA 120 135 11.5 SDA 120 140 11.5 SDA 120 140 15 SDA 130 145 12 SDA 135 150 12 SDA 140 155 12 SDA 4500 5000 0375